Safety & Health Management

Safety Control Makes a Company where Employees Are Happy

Safety and Happiness

Tailim supports the universal value of human beings who value life,

where no one is left behind.

Tailim’s “Safety and Health Management Policy”

Tailim has set the top management policy for 2022 as a <Safe and Happy Company>, and established a “Safety and Health Management Policy”

Tailim declares a “Safe and Happy Company” as its core value based on the CEO’s philosophy, and seeks to establish and practice policies with the support of employees and stakeholders.

- Ⅰ. We put the lives and safety of our employees, partners, and customers as our top priority and strive to achieve our safety goals.

- Ⅱ. We never compromise on safety, and must comply with safety and health-related laws and regulations and standardize them in-house.

- Ⅲ. With consistent education and training, we raise our capabilities with active practices so that safety and health become part of our daily culture.

- Ⅳ. We disclose the safety and health management policy, and continuously improve our system with stakeholders.

- Ⅴ. All executives and employees, including the CEO, must comply with the codes above.

January 3, 2022

Yi Bok-Jin, CEO

Tailim’s “Safety and Health Goals” in 2022

Tailim has selected “Happiness at Workplace” as its core value in Vision 2025. As the “Safety and Health Management Policy” was established in 2022, we have also established specific <Safety and Health Goals”> to create a people-centered and safe workplace.

-

Core Values

A Spirit of Challenge, Focusing on Talent,

Happiness in the Workplace, Win-Win

-

Management Policy

For everyone’s safety and happiness

For core values

For sustainable development

Ⅰ. Efforts to achieve safety goals

Establishing and implementing annual action plans for each safety goal

- Since the level and situation of safety control are different for each business site, we establish and implement appropriate annual goals for individual business sites.

Introduction of risk assessment for all worksites.

- When installing new machinery and equipment or changing the process

- When working with contractors and issuing task permits

Reduction and removal of risk factors with safety diagnosis and self-inspection

- Implementation of safety diagnosis by an independent third-party institution; improvement of risk factors

- Imposing risk factor control KPIs by supervisors

- Ensuring safety control by occasional assessment of workplace safety

Ⅱ. Compliance with applicable related laws and regulations

Absolutely prohibited from entering areas with machinery and equipment in operation

- In exceptional cases where workers are required to enter live machinery, it should be documented and at least two safeguards should be provided

- Establishment of an emergency response plan and emergency drills such as suspension and evacuation

- Level control, lock-out and tag-out according to hazardous facility access control guidelines

Fulfilling roles and responsibilities by each member of the safety organization

- Strict compliance with applicable regulations, guidelines, and manuals enacted and implemented

- Clarification of roles and responsibilities of managers and supervisors in personnel regulations and delegation rules

Ⅲ. Building up capabilities and cultures with continuous education and training

Thorough implementation of safety and health education

- Implementation of practical TBM education with reasonable rationales

- Regular training for supervisors in charge of control

- Group training for at least 1 hour per month (other than TBM)

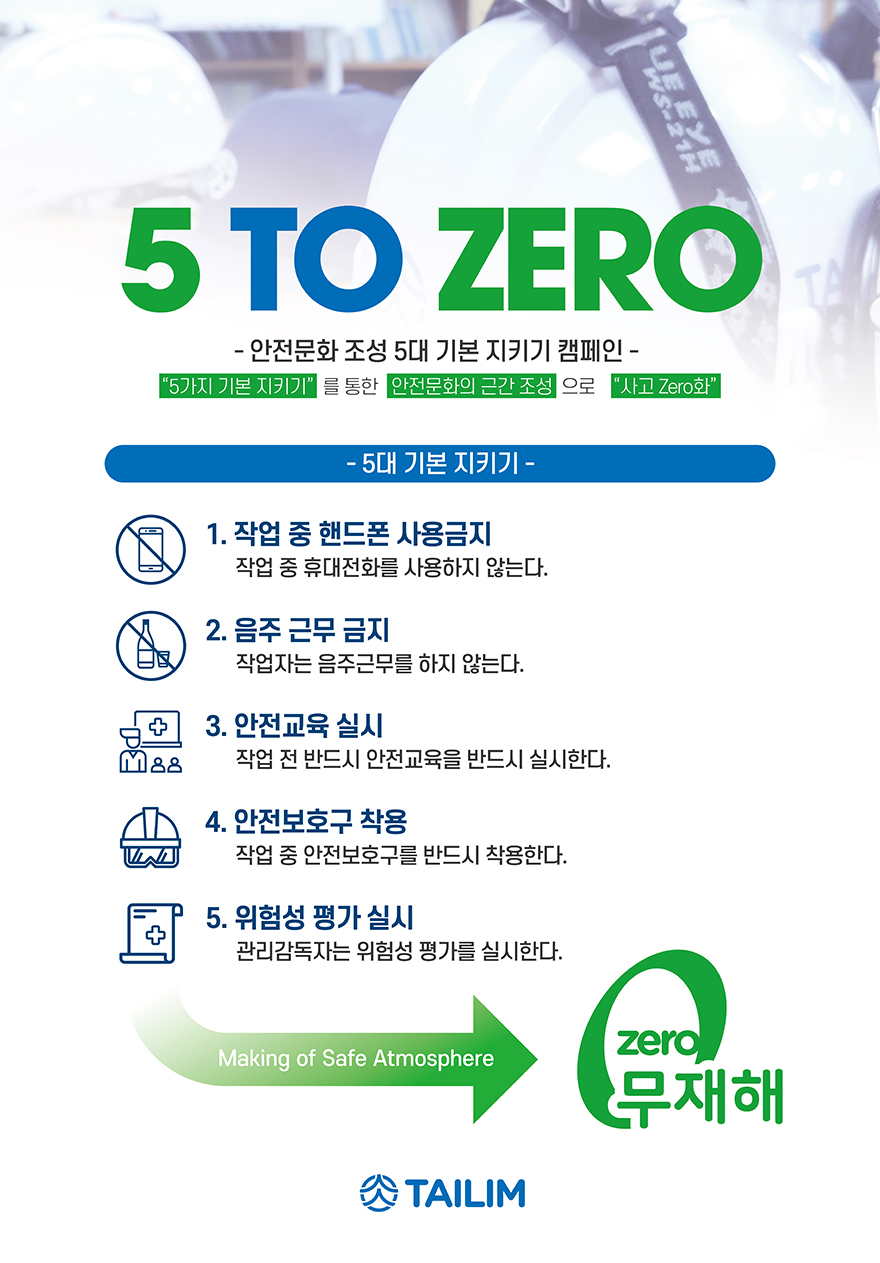

Promoting 「5 to Zero」 campaign

- Wearing safety gear, prohibiting mobile phones while working, prohibiting drinking and working, providing safety and health education, and conducting risk assessment at all times

Ⅳ. Disclosure of policies, establishment of cooperation system, and continuous improvement

Acquiring KOSHA MS certification for all business sites in relation with ISO

- Plan to acquire certifications for all business sites by 2022

- Businesses operating the ISO system will be linked with KOSHA MS

Plan to sign safety and health MOU with suppliers to strengthen safety control

- Budgeting for safety control expenses

- Safety control screening when choosing a supplier; conclusion of safety and health MOU when signing a contract

Ⅴ. Thorough implementation of policies for all employees, including the CEO

Designating safety assessment results and safety and healthcare roles as KPIs to be actively reflected in HR

Safety and health contests; presentation of best practices for safety control upon job reporting

- Annual PA and PKG best practices will be awarded by department

- Template for presentation of best practices included in quarterly report

Safety Campaign “5 to Zero”

Safety is established when all stakeholders faithfully follow safety rules – we aim to achieve the goal of <Accident-Free Workplace> by fostering a safety culture with the “5 To Zero” campaign.